Post harvest management

Fruit coatings to extend the storage life

Pectin coating (1%) alone or MA packing of

non-coated fruits in micro-perforated (0.0125%)

cryovac film could alleviate CI and extend the

storage life of Alphonso mangoes upto 4 weeks at 8°C

followed by 1 week (including ripening) under

ambient conditions (27.0-34.3°C). Integration of

both the treatments had no additional beneficial

effect

|

|

|

|

|

Post

harvest management Post

harvest management |

|

|

|

Modified Atmosphere packaging of Mango (

Alphonso and Banganpalli)

|

|

Mangoes individulaly packed in micro perforated

PE or PP Films extend the storage life to 1

month at 8 degree C with out chilling injury. |

|

|

|

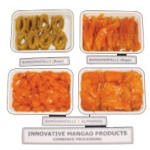

Innovative mango products

|

|

In an experiment conducted to develop

low sugar osmo-dried ripe mango slices of Alphonso, a

process was standardized using ripe fruits slices and

the final product had 7% less sugars compared to the

normal osmo-dried slices. The final yield of the product

was in the range of 15.3

- 28.2% and moisture content

was 13.26 - 26.25% based on the treatments.

|

|

Blended RTS beverage from mango :

The beverages will act as natural fruit nutrient

supplier and useful for thirst quenching.

Unit cost : Rs. 1.50 packing of 1 kg. produce.

Mango fruit is an excellent source of Vitamin-A. Both

mango and mango products are popular in India and are

also in demand in many foreign countries |

|

Long term preservation of raw mango slices in

brine for use in pickling: Preservation of

fruits and Vegetables by fermentation and pickling is

one of the oldest methods practiced throughout the

world. In India, pickling is done on a commercial scale

and has become one of the major food industries in

recent years. Among various types of pickles produced

mango pickles are in great demand both for domestic and

international market.

Input: Seeds of the variety (i) Raw

mango (ii) Salt (iii) Storage tanks, drums (iv)

Permitted additives and Preservatives.

Specific benefits: The feasibility of

process for commercial adoption has been successfully

tested in pickle industry. A high economic return is

envisaged by the adoption of this process which

significantly reduces the microbiological spoilage,

eliminates the problem of softening resulting in

machines and ensures good retention of colour, flavour

and texture in finished pickles. The potential benefit

of this process can be realized in the reduction of

spoilage during storage of slices and also in the

production of pickles with uniform quality.

Description: Pickles are generally prepared

from immature or mature unripe mangoes with or without

peeling/destemming, using salt and different spice

formulations to provide a wide range of flavour, taste

and quality. Acidic and fibrous varieties are ideally

suited for pickle production. Raw mangoes required for

pickling are available only during a short period of 3-4

months of cropping season. This necessitates

preservation of these raw mangoes for extended period

for pickle production round the year. Traditionally

mango pieces are stored by dry salting process. This

method involves storing mango pieces over layers of

salt. Changes in colour, texture and microbiological

spoilage are the common problems associated with this

method. To overcome these problems, a brining method of

preservation has been developed at the Indian Institute

of Horticultural Research, Hessaraghatta, Bangalore.

|

Snack food: A

preliminary trial was conducted to develop a snack food

using shredded raw (Totapuri and Banganapalli) and ripe

(Alphonso) mango fruits. The finalized product was a

dry, highly palatable and a storable snack. Further

studies on quality parameters are under progress.

Effect of gradient temperature conditioning storage on

fatty acid unsaturation, reactive oxygen species,

antioxid- ant enzymes and chilling injury in Alphonso

mango.

Matured Alphonso fruits were stored at 5°C with or

without gradient temperature conditioning (20 to 8° C

over duration of 15 days). Visible chilling injury was

completely absent in gradient temperature conditioning

treatment at the end of 30 days of storage. However at

5°C storage, 30% of fruits showed the visible chilling

injury symptoms. Total carotenoids and fatty acid

unsaturation were more and production of reactive oxygen

species was less in gradient temperature stored fruits

compared to direct storage at 5°C. |

|

|